What is the structure of a katana?

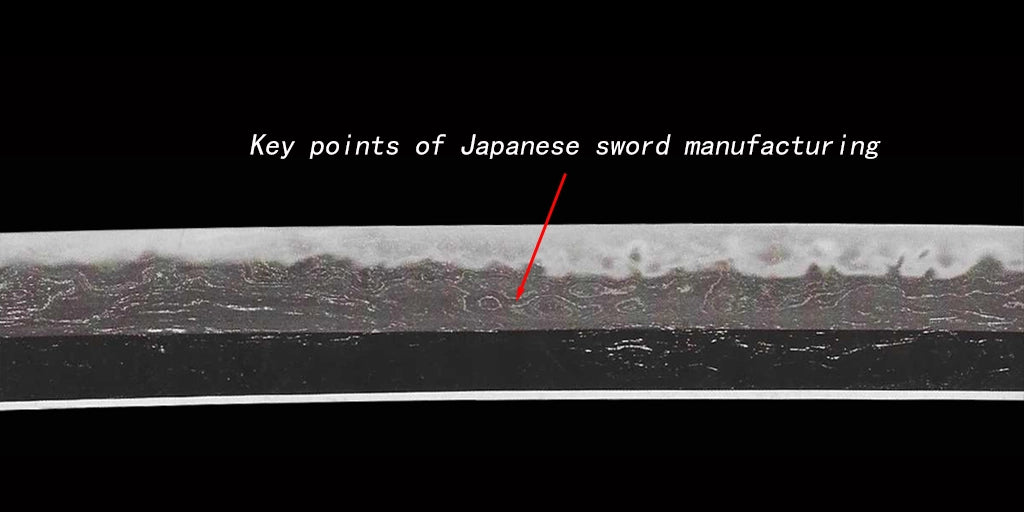

The nature of katana depends on the steel used, so understanding the unique characteristics of traditional katana steel will aid in appreciation. Broadly speaking, steel is a combination of iron and carbon.Katana is characterized by the use of shingane, which is soft and has a low carbon content, wrapped and forged with ka-wagane, which has a high carbon content. This is called construction, and since the nature of katana depends on the steel used, understanding the unique characteristics of traditional katana steel will aid in appreciation. Broadly speaking, steel is a combination of iron and carbon, and the softer steel is used as a core to create the central area of the sword, with the core functioning as a shock absorber to keep the blade from breaking under extreme pressure. No breakage, no bending, and very good cutting performance are the main points of katana's promotion,advanced players who understand this often pursue custom katana with this composite steel blade.

What are the structures of the Katana blade?

Shintetsu, refined by forging, has good elasticity but low hardness, while kawatetsu has the opposite effect. Therefore, kawatetsu is folded into a "J" shape, wrapped outside of shintetsu, and then forged into the initial prototype of the Japanese sword, which is the most commonly used "kobuse gitae" method. When high hardness steel is used as shintetsu and low hardness steel is used as kawatetsu, it is called "gyaku kobuse". Among them, maru gitae is the simplest, but the requirement for iron quality is also relatively high, otherwise it will significantly affect the quality of the sword. Therefore, it is not the cheap goods that some people imagine that are often used. Many famous craftsmen, including the famous Kotetsu, have Maru Gitae works. In addition, as a traditional forging method, the premise of Maru Gitae must be folding forging. In addition, there is the "Sanmai gitae" method of clamping steel, which means that two pieces of low-hardness steel clamp one piece of high-hardness steel, and then add two pieces of medium-hardness steel, called "Gumai gitae". Similarly, there are Susho gitea, J ū Gomai k ō Buse - gitae et al. Hon saimai "is an additional piece of" Munetetsu "with lower hardness added to the blade back on the basis of Sanmai-gitae, and there are dozens of combinations. Kobuse gitae is the most commonly used method of hammering kawatetsu into a rectangular flat plate, rolling it vertically, and wrapping it with shintetsu. This method may seem simple, but it is not easy to master. The difficulty lies in the fact that if the bond between the shintetsu and shintetsu is not tight enough, bubbles may be mixed in. If bubbles are present, pinholes must be drilled and forged quickly to squeeze out the bubbles as much as possible. After forging the soft and hard parts together, slowly hammer them thin to create the shape of a sword.

1.Maru-gitae: Heat the steel material until it is red hot and repeatedly fold and strike with silver, separating out impurities from the raw material, making it a material with uniform texture. Due to being forged from a single piece of steel, the overall toughness of the blade is relatively poor, and the shock absorption is slightly poor when chopping and breaking with force. It is easy to break when chopping or cutting with other swords

2.Wariha-gitae:Compared to Maru gitae, Wariha gitae has better elasticity and toughness. Wariha gitae is forged from a combination of hard and soft, with a hard edge that is easy to chop and a soft blade that is not easy to break.

3.Kobuse-gitae:The use of hard steel wrapped soft steel technology enhances the overall toughness and shock absorption performance of the blade due to the use of relatively soft materials in the inner core of the blade. The overall toughness, blade hardness, shock absorption during chopping, and fracture probability of the Sanmai-gitae sword are all stronger than those of the Sanmai-gitae sword.

4.Makuri-gitae:With iron as the core and steel as the outer shell, compared to Maru gitae, it retains the hardness of the blade and blade, while the iron on the back and core improves shock absorption and anti fracture performance.

5.Sanmai-gitae:The blade adopts folding forging technology and the core adopts hard steel technology, which makes the hardness of the blade different from that of Shingane, and the hardness of the blade is high. The blade is made of three pieces of steel folded and forged, which is not easy to break. The blade toughness, shock absorption during chopping, and fracture probability are stronger than Maru gitae.

6.Hon-sanmai-gitae:With iron as the backbone and steel as the blade sandwiched between two layers of iron, the blade is folded and forged with a soft iron back and high carbon hard blade Made of steel, the entire blade combines hardness and softness, increasing its toughness, shock absorption, and fracture probability compared to Sanmai-gitae.

7.Gomai-gitae:Improved on the basis of makuri gitae, the blade back is sandwiched with hard steel to increase the hardness of the blade back and enhance the blocking ability in practical combat.

8.Shihozume-gitae:Adopting a folding blade to enhance the overall toughness of the blade, the blade back is made of hard steel to avoid damage to the blade back in actual combat. The blade core is made of soft steel to improve toughness, and the blade is forged with high carbon hard steel Hamon, which maximizes the rigidity and flexibility of the blade, enhancing toughness, shock absorption, and bending resistance. Due to the complexity of the process, it requires a forger to master the highest level of forging technology in order to complete it.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.