Jihada and jigane-Folded steel katana

What is jihada and jigane?

The steel (jigane) on the surface of a Japanese sword has a definite color and texture, and since the steel has a very dark appearance, it requires a good grind to bring out the details. Examining a well-made and ground Japanese sword usually reveals a clear color and fine texture. In addition, it is common to observe the distinctive surface pattern created by repeated folding during the forging process, called jihada, which varies from sword to sword depending on the method of steel making and the steel used by the sword maker for a particular sword. In addition, the folding method varies from one school to another, so the jihada is an important feature for identifying the schools of swordsmiths. while the jihada of koto period swords varies from region to region, the jihada of shinto period and onward swords does not vary from region to region, but rather from one swordsmith to the next. In addition, the jihada pattern of a sword can be easily distinguished only if it is very well polished. Therefore, when evaluating Japanese swords, the surface texture, color, and jihada are all characteristics that need to be carefully observed. The following are jihada patterns of Japanese swords forged by various swordsmiths at different times in history.

Itame-Hada

Soshu-den works of the famous blacksmith Masamune and the works of the

Hoki province (Tottori and Shimane prefectures). A tightly forged itame or ko-itame hada is often seen on the works of the Yamashiro (Kyoto) smiths of the Kamakura period; particularly fine, well-forged works are referred to as nashiji-hada (Japanese pear skin).

Masame-Hada

Mokume-Hada

Nashi-ji Hada

Ayasugi-Hada

Ayasugi-Hada is formed by artificially bending masame-hada. It is shaped like parallel waves. This forging method is used only by the gassan school, so it is also called gassan-hada.

No-ji style

In addition to hamon, the texture of the forging is not visible. Although the texture is not visible, the workmanship is still folded and kneaded, but the folding method is different from that of other genres, resulting in the disappearance of the texture, which is known as the no-ji style. This forging method was created by Kazuhide Ikeda, a disciple of Suishinshimasahide, the originator of shin-shinto (at the beginning of the 19th century), and because no jihada can be seen, it can easily be misinterpreted as a mass-produced model decorative sword made in a factory. The ji-less style of blade can be easily confused with an ancient handmade sword or a modern mechanized sword by considering the hamon, the shape of the blade, the stem, and other parts of the blade.

Nioi and Nie

How many times is steel folded to make a katana?

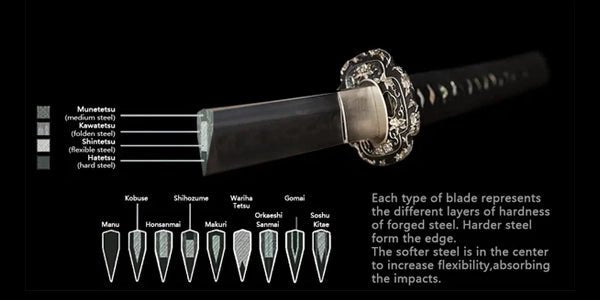

The process is very complicated, there are fifteen folding processes, in fact, each folding requires a thousand hammers to give it a long length, and also in the charcoal fire to remove impurities. After fifteen folds, a katana, at the very least, has 30,000 layers of steel in it, which should be called a thousand hammers. That is why katana first of all does not break easily, it is very hard, it does not bend easily, it cuts sharp, and it is only in the process of folding that the beautiful jihada is presented (Also known as composite steel with structure).

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.