What are the best steels for Katana?

Do you know which types of best steel for katana are available?

The best steel for Katana should consider the following points: hardness, toughness, brightness, and whether it can increase multiple grinding processes. Of course, there is also beauty, which is what collectors are most concerned about.here, we will introduce some commonly used steel materials for making Katanas, When customizing katana, you can choose the blade that suits you based on your own needs and budget.

1060 steel (Low cost steel suitable for beginners)

Chemical composition

C: 0.55-0.65

Si: 0.17-0.37

Mn: 0.60-0.90

S: ≤ 0.050

P: ≤ 0.040

Cr: ≤ 0.25

Ni: ≤ 0.25

Cu: ≤ 0

The most common steel used to make Japanese swords is 1060 steel, as it balances elasticity and hardness. When made in the correct tempering method, it is the best carbon steel for making functional Japanese swords. It can maintain its hard and strong blade. At the same time, due to its low price, it has become the most suitable steel for beginners and outdoor players.

T10 steel clay tempered Hamon (Players with certain performance requirements)

Chemical composition

C: 0.04

Si: 0.03

Mn: 0.1

S: ≤ 0.015

P: ≤ 0.025

Cr: ≤ 0.1

Ni: ≤ 0.2

Cu: ≤ 0.15

The T10 steel blade is very hard, even stronger than the 1095 carbon steel blade. Its relatively high carbon content makes it very strong and can withstand many surfaces that you may hit. Although it requires proper maintenance, its resistance to scratching, scuffing and wear is very high due to the presence of tungsten. This also means that its price is higher. The blade made of this material is more suitable for players who have certain requirements for the performance of Japanese swords.

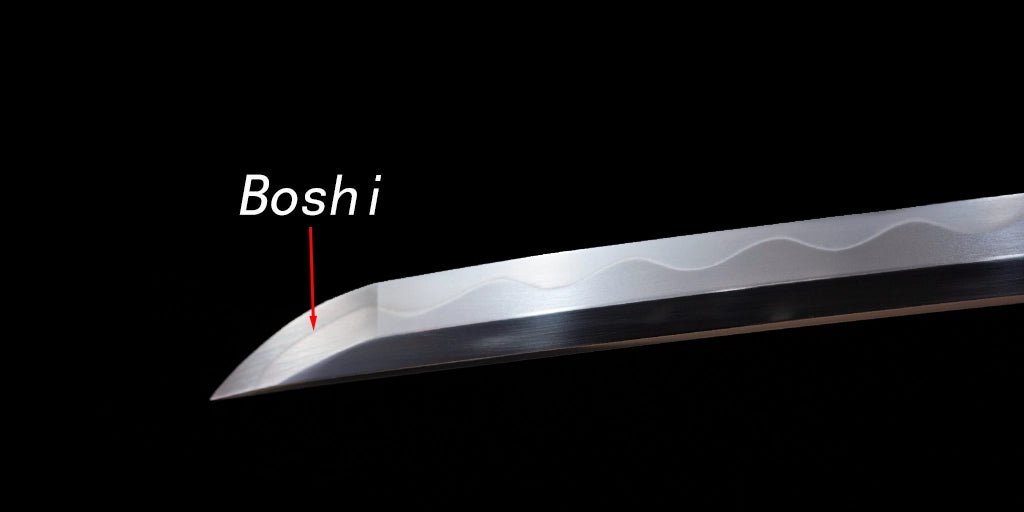

What is Hamon?

The so-called "Hamon" is a professional term for covering the blade with soil and burning it. The blade is covered with soil that does not require high hardness and then heated to a certain temperature. When the red and hot blade enters the water, the bare part cools quickly, while the temperature change in the part covered with soil is not very significant, resulting in a difference in hardness from the bare part, achieving a combination of hardness and softness. In the case of high blade hardness, still able to maintain the good toughness of the blade.

Damascus steel (More suitable for intermediate players who pursue aesthetics and collectibles)

C: 1.2-1.6

Mn: 0.2-0.8

Si: ≤ 0.25

Cr: ≤ 2.0

Mo: ≤ 0.3

Advanced grinding (Suitable for advanced players pursuing ultimate performance and collectibles)

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.